-

-

-

Total payment:

-

1. CULTIVATION

Satoen Vietnam’s Japanese tea garden is cultivated on the Van Ho-Moc Chau plateau, with the advantage of favorable terrain and climate along with a self-contained self-management process and high-tech farming techniques. Therefore, the tea tree is always healthy and produces fresh, green and soft tea buds that meet standards.

2. COLLECTION

The first tea harvest of the year usually starts from the end of March, the harvesting technique is completely by a modern picking machine, high-class tea products are picked 1 shrimp with 3 young leaves and 1 shrimp with 5 leaves for common products.

After harvesting, fresh bud tea are immediately transported to the factory when the bud tea are still fresh to ensure the best quality for the finished product after processing.

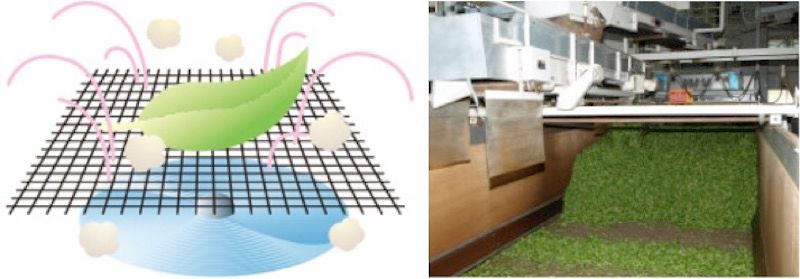

3. FRESH STORAGE

Ventilation / humidification

Tea buds are temporarily stored in a specialized large tank to avoid abnormal metabolic fermentation in the tea leaves, to preserve and maintain the freshness of the leaves, so the storage box is provided with strong breezes with moisture air.

4. STEAM

by hot steam

Fresh tea buds are put into an automatic steamer, hot steam at high temperature is provided continuously and directly affects the tea leaves to stop the fermentation of amino acids and reduce the content of tannin in the tea. The time for tea leaves circulating in the steamer is about 30-50 seconds, depending on the production setting method, the steaming time could be fast or slow.

5. COOLING

After being steamed at high temperature, the tea buds are immediately put into the cooler, the tea leaves will receive controlled impact winds. The temperature of the tea leaves will also be reduced to the needed minimum so as to prevent abrupt color change and always keep characteristic green color.

6. QUANTITATIVE INVERTING DRY

In order to improve the color and flavor of the tea leaves and shorten the time of subsequent coarse drying. Inverting is done by blowing hot dry air while rubbing the tea with moderate pressure on the tea leaves to remove Dew vapor condenses on the surface of the tea leaves after steaming appropriately in order to soften the tea leaves and reduce the water content inside.

7. DRAWING

To make up for the shortage in the previous drying process, the tea will be drew by compressive pressure from the machine cage and the counterweight on the top of the tumbler. This process causes the leaves to clump and rub with pressure without heating, in order to break the tea leaf tissue, facilitate washing process to release the ingredients through the leaf bruises.

8. ROLL DRYING

The pressure from the hand shaker is resonated with the fast rotation speed of the machine and the hot air temperature, so the surface of the tea leaves is gradually dried, a basic twist of Sencha green tea is formed.

9. POLISHING & STRAIGHTENING

An affirmation of the difference in appearance of Japanese Sencha from other teas, is established at this stage. Temperature still plays an important role for drying evenly, the reverse pressure is continuously changed automatically combined with the strong massage friction force from the brush and specialized cloth, so the shape of tea changes gradually until it becomes elongated, thin and small.

10. DRYING

Tea is circulated evenly through compartments of dryer, to ensure tea flavour and have long storage, drying to a remaining moisture of about ≤ 6%.

11.SEPERATION & CLASSFICATION

For convenience and easy in taking only finished tea, it is important to classify tea sizes, next step is the separation of shells and impurities mixed in the tea if any.

12. QUALITY CONTROL

Quality control to maintain consistently good quality, and detect and eliminate unsuitable factors.

13. MIXING & PACKING

Matcha green tea products are packed in aluminum bags according to the declaration file conformtable with food safety regulations, the packing volume depends on requirement of customer valid order.