-

-

-

Total payment:

-

1. CULTIVATION

Satoen Vietnam’s Japanese tea garden is cultivated on the Van Ho-Moc Chau plateau, with the advantage of favorable terrain and climate along with a self-contained self-management process and high-tech farming techniques. Therefore, the tea tree is always healthy and produces fresh, green and soft tea buds that meet standards.

2. COLLECTION

About 15~20 days before harvesting, the tea garden is covered with a black net to isolate it from direct sunlight. During this time, it will be an important requirement to determine most of the quality of the nutrients available in the tea leaves.

Harvesting conditions require strict management and proper procedures. Depending on the needs of the product quality and the health of the tea plant, the method of harvesting is decided, usually, after removing the net covering for about 15 to 30 minutes, it must be harvested, tea buds, one shrimp, three leaves If hand-picked or one shrimp, 4-5-leaves if picked by machine, at this time the color of the buds and fresh tea leaves are typical dark green. Tea buds will be quickly transported by specialized soft cloth bags to the production area.

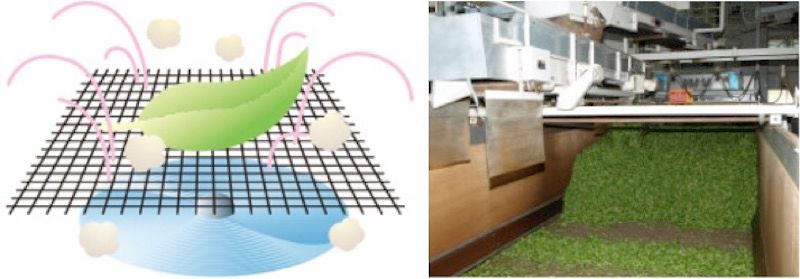

3. FRESH STORAGE

Ventilation / Humidification

Tea buds are temporarily stored in a specialized large box to avoid abnormal metabolic fermentation in the tea leaves, to preserve and maintain the freshness of the leaves, so the storage box is provided with strong wind contain moisture air.

4. STEAM

by hot steam

At this stage, fresh tea buds are put into an automatic steamer, heat and hot moisture are provided to directly affect the surface of the tea leaves, in order to stop the fermentation of amino acids and yeast in the leaves. At the same time, it also creates a characteristic aroma of fresh tea leaves.

The tea leaves are stirred in the steamer cage by the shaft and the cage rotates for about 15~20 seconds.

5. COOLING

After being steamed at high temperature, the tea leaves are immediately put into the cooler, the tea leaves will receive controlled impact winds, the temperature of the tea leaves will also be reduced to the needed minimum to prevent sudden color change and always keep the characteristic blue color.

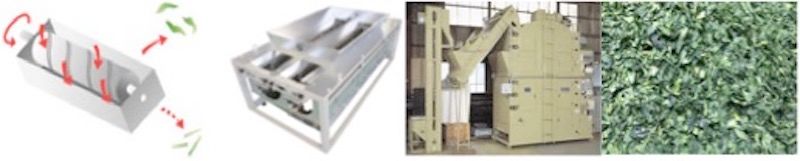

6. CUT & STAMP

It acts as a tea leaf & jar press machine to let the water components continue to escape through the stamping gaps of the leaves, and at the same time helps to make the next drying stage faster and more evenly, this stage also helps the tea leaves to keep nice stable blue color.

7. DRY

+ Coarse drying : After being cut and stamped, the tea leaves are regularly put into conveyor dryer with ventilation mesh for hot wind to circulate, the tea leaves are put into the hot air about 120~130o and circulated on conveyor about 4~6 minutes, the water component is quickly drained but still remains safe green.

+ Drying: Temperature of the hot winds is reduced around 90~110oC but the circulation time of the tea leaves is increased to 10~12 minutes in the hot air. During the drying process, thanks to the action of the island shafts and hot wind so the tea leaves are dried quickly and evenly, and the aroma of tea begins to be formed basically, and has the original aroma.

8. SEPERATION

- Cut, Rotate, Sort: Although it has undergone the drying stage, a component of the leaves and branches of the tea buds still has a significant amount of moisture inside. Therefore, in this stage, the horizontal rotary axis of the machine is used. to separate the leaves, bones and pulp of tea leaves

- Classify by wind: The leaves and leaf pulp are further classified by the wind generated in the machine cage.

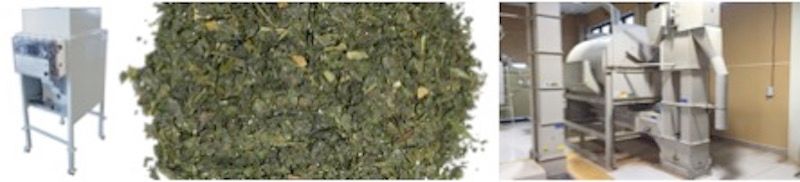

9. SEPERATION

- Cut, Rotate, Sort: Although it has undergone the drying stage, a component of the leaves and branches of the tea buds still has a significant amount of moisture inside. Therefore, in this stage, the horizontal rotary axis of the machine is used. to separate the leaves & bones tea leaves.

10. COARSE GRINDING FOR FINISHED PRODUCTS

Tencha after being dried will be preliminary crushed according to production needs, size of the product is determined by the size of the grinding meshes.

11. MIXING FINISHED PRODUCTS

After finishing basic production, Tencha is put into the mixer compartment, and then rotated for about 45 minutes to create a general uniformity of the entire product throughout the production process.

12. PACKAGING & STORAGE

Products are carefully packed into each Carton and vacuum aluminum bag, then stored at room temperature

13. GRINDING MATCHA

TENCHA is put into an automatic specialized grinder in a separate grinding room, combined with an automatic vibrating screen, so the fineness of Matcha is always guaranteed from 10μ~15μ, during the grinding process.

14. QUALITY CONTROL

Quality control to maintain consistently good quality, and detect and eliminate nonconformities.

15. PACKAGING

Matcha green tea products are packed in aluminum bags according to the declaration of conformity with food safety regulations, the packing volume depends on each valid order request of customer.